Customization

Alone we can do so little, together we can do so much.

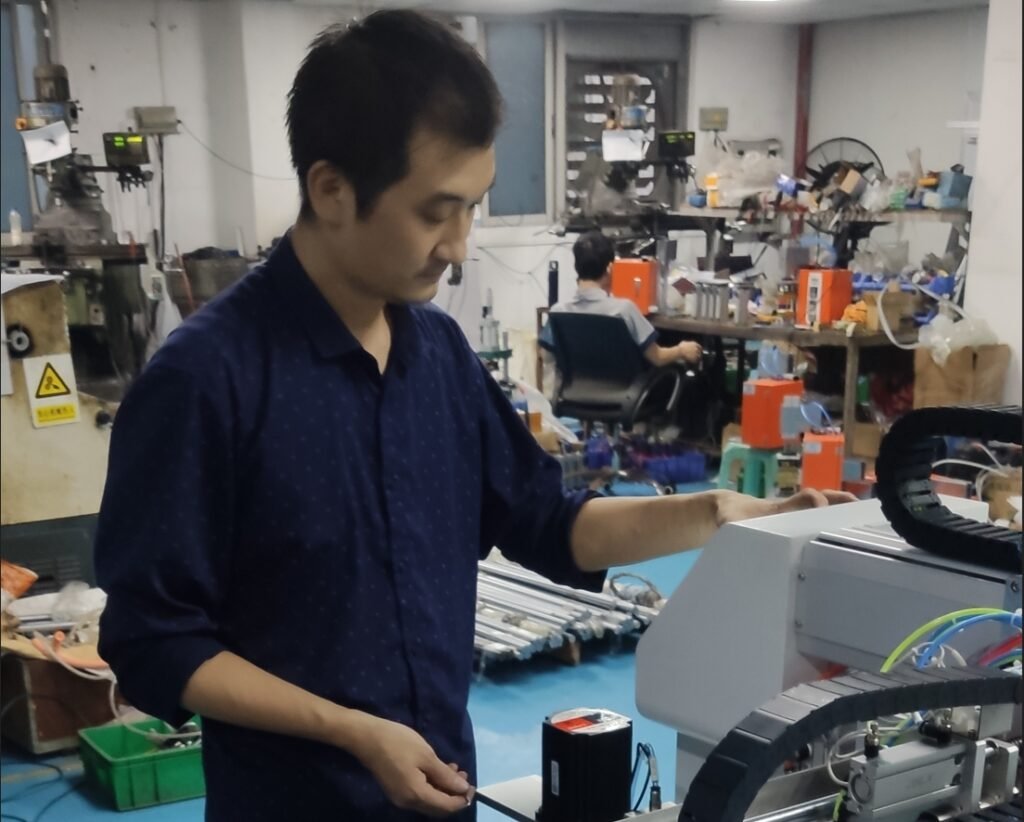

Meet Our Team

Teamwork makes the dream work

Engineer leader

Mechnical engineer

Mechnical engineer

Assembly engineer

Programming engineer assistant

Machine structurer designer

PLC programming engineer

Assembly assistant engineer

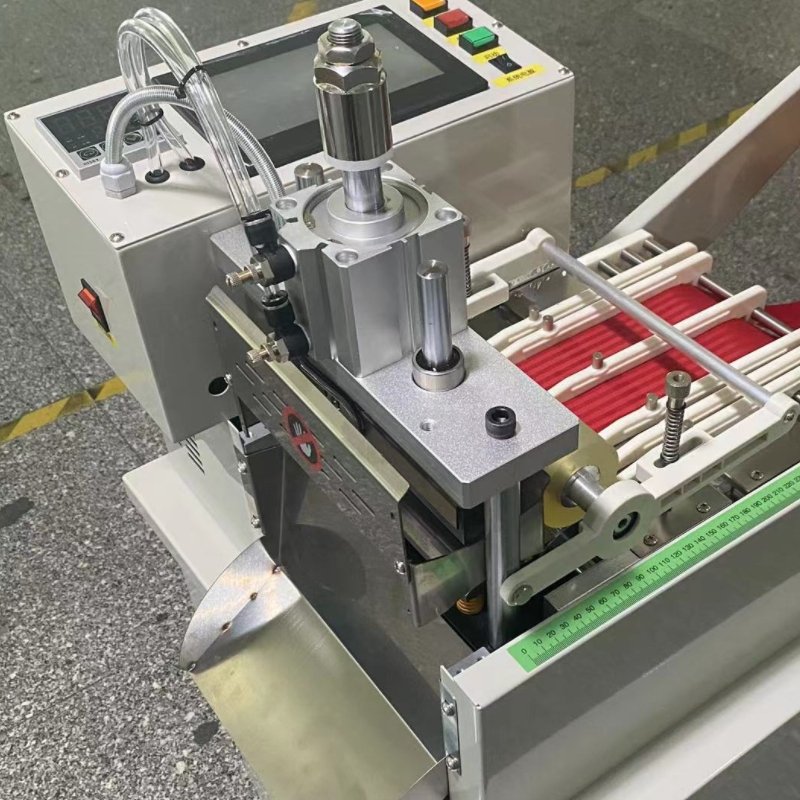

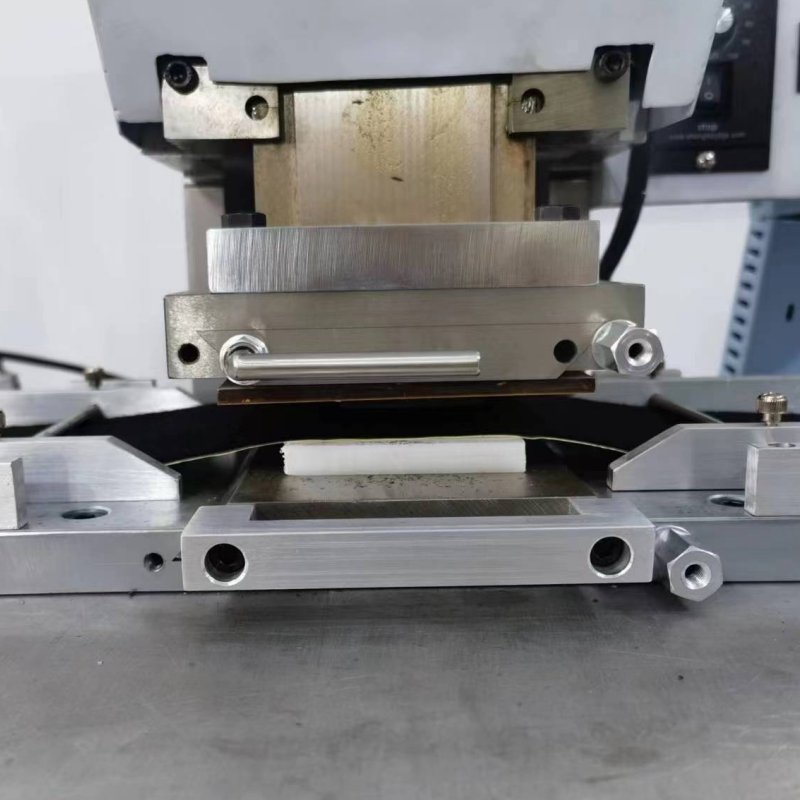

Customise cutting machine with additional automation process

ESMAI design and manufacture the customised cutting machines with additional automation process combined in one machine, for example, our silicone o ring gaskets fully automatic cutting and bonding machine ES-060 , draw silicone gaskets to fixed cutting length and cut the gaskets to fixed length, dipping both ends silicone gaskets with silicone adhesive and place the adhesive dipped gaskets in the hot mold ,the hot mold will heat adhesive to cure and form a good bond of silicone oring gaskets .the bonded oring gaskets will be taken by the mechanial hands and fowarded to the collection bands , all other automation process can be added on the customised cutting machine like below automation process.

Gluing

Gluing two parts material together after dipping the material with glues and place in the hot mold to cure and form a bond

Winding

Wind material into rolls like silicone tubes ,ropes ,velcros and other material etc. winding speed can be set ,winding circle amount to be set

Stacking

Like stacking the cut to length velcro in good order that will be easy to collect and direct to packing by workers

Assembly

Assemble two material together , like assemble the silicone oring gaskets to the food container cap lids ,so the food container cap lids will have silicone oring gaskets fitted inside etc.

Laminating

Laminate adhesive tapes with other material , like silicone strip with double side tapes ,rubber strip with 3M tapes etc.

Clamping

Clamping two parts together ,like clamping a metal wire on two rope ends to form a rope loop . the clamped rope loop is strongly bonded by the clamped metal wires

Inspecting

Inspecting the processed product by the machine if meet with quality requirement . like inspecting the bonded silicone oring gaskets if all pcs are bonded well with pulling test device ,after going through pulling test requirement ,the good bonded oring gaskets will be fowarded for collection and weak bonded oring gaskets willl be passed out and separated from the good ones .

Knotting or other automated process

Other automation process also involves taping ,hole punching, stripping ,case inserting and some other process which customers requies us to customise and add for them etc.

Basic cutting

Basic cutting is the primer function of a customised cutting machine , it involves various cutting metholds such as corner angle cutting ,high speed cutting , lathe cutting , die cutting and kiss cutting and slitting cutting etc , ESMAI can customise the basic cutting method &techniques according to customer’s needs

Angle cutting

Angle corner cutting means the cutting knife can automatically rotate to a preset fixed angle for cutting the material, such as 45° cutting on the left and 45° cutting on the right, to cut bevels of different shape pattern

High speed cutting

High-speed cutting means to apply high-power servo motors to achieve fast cutting, generally for products with small cutting lengths and high output requirements, such as rubber bands and silicone gaskets.

Ultrasonic cutting

Ultrasonic cutting refers to seal cutting edge of product without fray and the cutting edge should look natural and compare to hot cut , the sealed cutting edge is without dark . ultrasonic cutting meets demand of customers with high requirement for cutting edge

Hot air motivated cutting

Hot cut applies blunt knife with application of air cylinder on top to maximize the cutting force and heat tube to elevate knife temperature up to 650 degrees for cutting and heat seal thick and large size material like big ropes , thick webbings etc. .

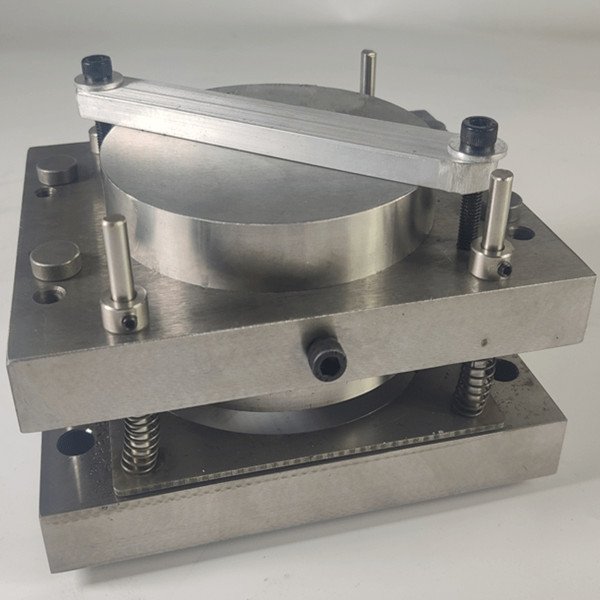

Die cutting

Die cutting means the mold will be made of the shape of customer’s cutting material and with high power motor to drive die cut mold to die cut material to shape

Kiss cutting

Kiss cutting refers to cutting adhesive material with back film or paper . By adjusting the knife cutting depth , it cuts to the adhesive material but not through the back film or paper ,by separating waste material from the kiss cut material , the material kiss cut to shape remains on the back film or paper and gets into roll form.

Lathe cutting

Lathe cut refers to a cutting process designed for products that require extremely flat and smooth cuts, such as silicone or rubber washer gaskets. In this process, the cutting blade operates at high speeds to ensure a flat cut while maintaining precise movement for accurate cutting lengths.

Other cutting method

Other cutting also includes slitting cutting , electronic eye precision cutting , laser cutting ,lathe vibration cutting ,rotation cutting and other cutting techniques.

How to make a customised cutting machine

1,Define automation solution

Firstly, customer will need to tell us all the production process to make his products , so we can design automation solution accordingly.like one of our customer ireland , he requires automation of a bundle rope , the customised machine achieves the automation of hotting cut rope to length, clip both ends ropes into a loop and gather all 50pcs of rope loops and bundle them together in one machine .

2, Manufacturing

Our mechanical engineer will sort out all the spare parts needed for all the automation that’s needed ,the motors ,the air cylinder, the moving rails and machine structure metal parts and make detailed drawings for the machine structure parts and foward to our workshop to make the parts and our soft ware engineers will make the PLC touch screen for the machine and design the programing for operation of the machine , the layout of electrical maps etc.

3, Assembly

After all spare parts of the machine are the ready , the sheet metal parts ,the aluminium extruded parts , motors ,air cylinder and air tubes ,motors ,plc touch screen and electrical parts of PCB, servo driver, wires . our engineer and worker staff will assembly all the spare parts and machine structure and put inside the wires and air tubes and do the necessary connection .

4, Machine test

After the machine is fully assemblied, our engineer will run enough test of the machine for the stable performance of the machine , firstly ,we will do empty run of the machine for some time and then we will load on the material for processing and check the machine if perform stablely . if not stable , we will keep improving the parts that affects the stable performance of the machine . at last step , the machine will go back to empty run for one week, our engineer will find out and define the wearable spare parts for customer to prepare as back up spare parts for long term maintainance after they receive the machine .

How to define a good machine

1,Practical &easy to use

The cutting machine will be designed on the basis of practical and easy to use. the machine automation working parts are made practical and reasonable and PLC touch screen is simple to use for workers , basis product prameter setting , working parts prameter setting ,manual mode ,alarm code which help customers to trace to specifical problem and with the solution to solve problem accordingly .

2, Labour saving

The customised cutting machine combines cutting and with other additional automations to save labour cost . like in customers’ real production , cutting silicone gaskets to length , dip silicone gaskets ends with silicone glue and put in hot mold to heat bond and take out bonded orings, we are just replacing all those production process with automations and putting them together in one machine

3, Great productivity

Productivity is prime purpose for a customer to let us design the machine and achieve automations to replace other labour to increase their productivity and make more money for them . so our engineer will cater to customer’s productivity requirement to design and produce the customised cutting machine

4, Stable performance

The customised cutting machine should be stable to use with as little maintainance effort as possible .so this calls for engineer to design the working units and struture on basis of simplicity ,the more simple and practical the designed working parts , the more stable performance the customised cutting machine can be and also choose good quality spare parts .