The silicone rubber strip tape laminating machine ES-073 is designed for automatically laminating all kinds of silicone gaskets profiles or rubber strips with double side tapes . this rubber strip tape lamination machine applies with mechanical hands to do first lamination and brace the laminating material straightly for the roller to do second reinforced lamination .

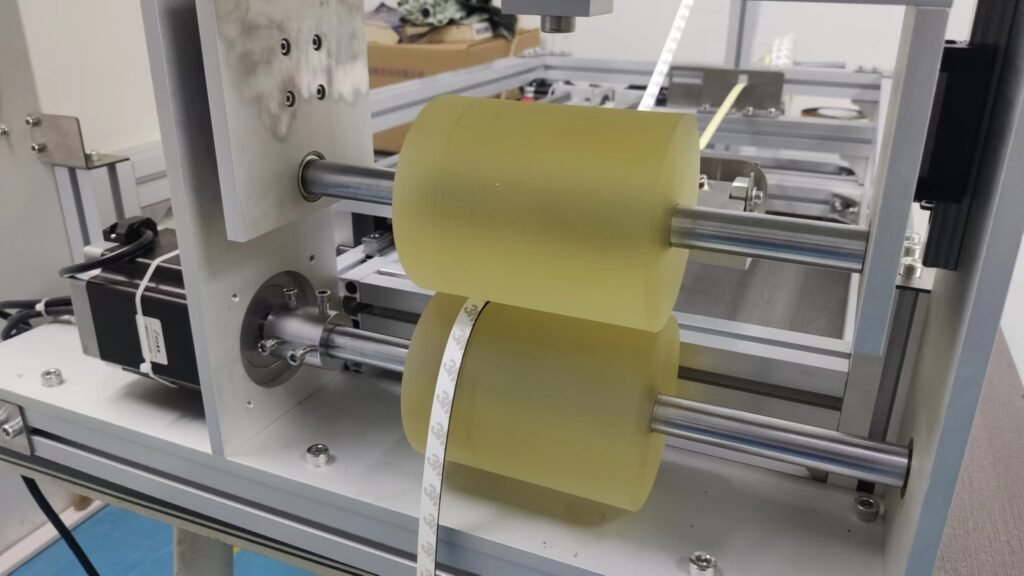

The laminating speed of this rubber strip with adhesive tape lamination machine is 500mm/s on average , customer can adjust the laminating speed based their production requirement . This foam gaskets tape laminating machine also had equiped with multi fixtures to lead the laminating material straightly for lamiantion which avoids dislocation between silicone&rubber strips and double side tapes. The roller plays the key role in lamination and the roller distance can be adjusted to different sizes of silicone gaskets profiles or rubber strip.

The foam gaskets tape laminating machine applies with touch screens and also simplified control buttons which will be easy to operate .

This self adhesive gasket strips press on machine had also backed up with a material collection device which can collect the laminated material into roll form and save the human labour to put laminated material in rolls for themselves .

【Product Advantage】

1, Wide application to all kinds silicone profile strips which needs sticking to double side tapes with mechanical hands to do prior lamination and brace laminating material to

roller to do second reinforced lamination

2, Good quality laminated material with fixtures to hold laminating material straight for lamination which avoids dislocation between silicone &rubber strips and double side tapes

3, Self collection of finished laminating material into roll form wihch save labour to collect and put the laminated material into rolls .

【Product Detail 】

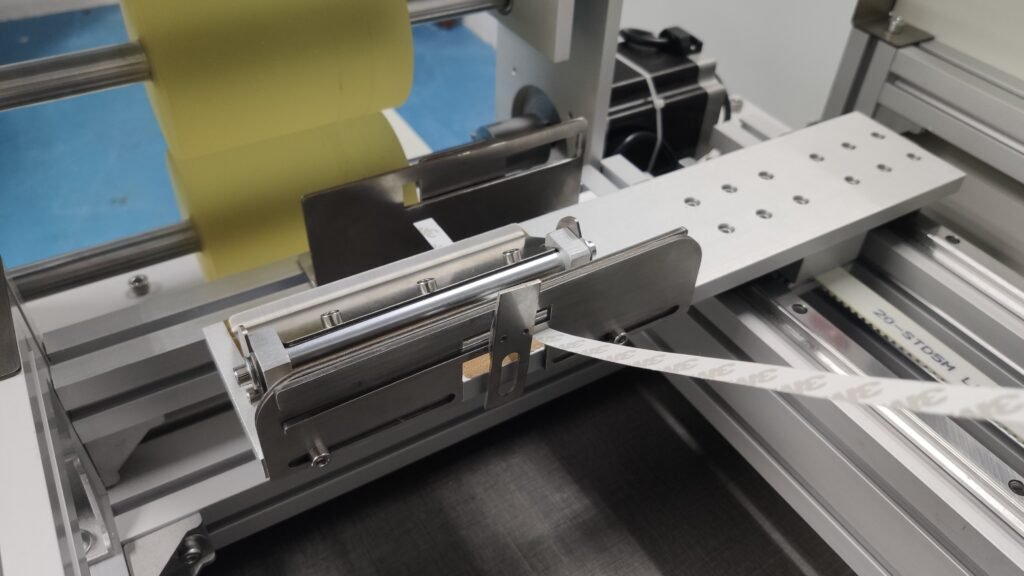

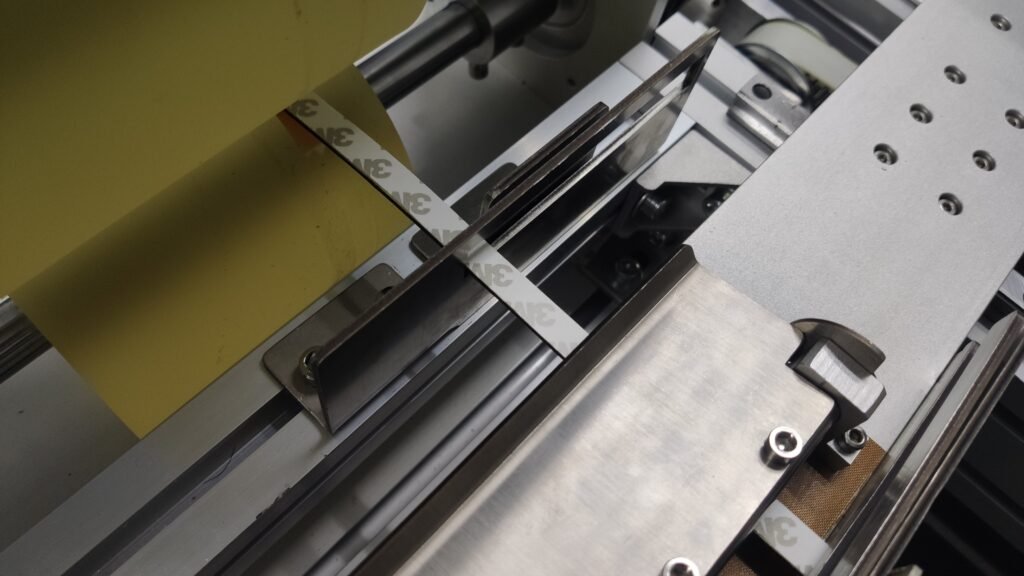

1,Mechanical hands to do the first lamination and then hold the laminating material straight and brace it for second lamination on the roller , the mechanical hands made it applicable to

all typies and shapes of silicone or rubber strips

2, Simplifed touch screen with button control which will be easy to operate ,customer can set the total lamination length based on their material length and also set laminating speed based

on their prouduction requirement .

3,Adjustable Fixture plate to hold and fix the strip and double side tapes in a straight line position to ensure lamination in correct position . the outside plate is movable to adjust the fixture holes

and fit with different width lamination material .

4, Roller laminating pressing ,the rubber roller plays the key role in lamination of strips with double side tapes ,the roller distance can be adjusted to hold different size silicone

or rubber strips and adjusting laminating pressure as well to make sure strips and double side tapes stick to each other just well.

5, Material collection device which ensures the laminated material will go into a roll and save labor, this device consists of motor and sensor , the sensor metal can feel pressure of laminating material and stop working to ensure laminating material is an loose status and work in harmony with laminating rollers ,the rolling speed can be adjusted based on laminating speed . there is a sensor metal