The webbing loop cutting and joining machine ES-094

Brand :ESMAI

Model No:ES-094

Country Of Origin :China

Certificate :CE

The webbing loop cutting joining machine ES-094

【Product Description】

The webbing loop cutting joining machine ES-094 is designed for ultrasonic cutting folding and joining the fabric into loop shape with full automation ,this machine is widely applicable for shoe manufacturers, promotional gifts, hand bags etc.

The cutting length ranges 1-99999mm , the processing speed is 110pieces/min on average ,It can switch between cutting &folding&joining mode and singular fixed length cutting mode which is wide application.

The shoe ear loop cutting folding bonding machine is also fitted with feeding arm at the tail which allow it to hold multi cutting material rolls and process up to 5 pieces of cutting material at one time which raise productivity.

The best advantage of this fabric loop cutting folding joining machine is that it combine cutting folding and joining the fabric into loop in one machine which save human labour and make it easy for seaming it on the shoe heels

【Product advantage 】

1, Utrasonic Cutting folding joining webbing fabric into loop in one machine , making a fabric loop in nice finish ,full automation and high productivity.

2, Easy to operate , the machine controlling system is simplied , it will be easy to manage the operation of this machine

3,Widely applicable to shoe manufacturers ,promotional gifts,hand or lifting bags

【Product Detail 】

1,PLC touch screen ,the machine had been equiped with touch screen and is easy to operate with simplifed controlling system ,easy to do settings

for folding&cutting mode or fixed cutting length mode .

2,Feeding wheels and sensors , the feeding equipment involves 15 feeding wheels ,each wheel is responsible

for feeding one individual gaskets ,the wheel will press down and roll the gaskets foward when the sensor wheels

in front are pulled up by the gaskets material

3, Two mechanical hands ,the two mechanical hands are made with cavities which fit sizes of silicone gaskets ,

they are responsible for drawing cutting length of silicone gaskets and dipping the silicone gaskets ends

with silicone adhesive (adhesive dipping times can be set on the machine) as well and place the silicone gaskets in the hot mold

4, Glue brush boards , the silicone gaskets ends will dip against the glue brush boards , the glue brush board

will be brushed with the glue for once after gaskets dipping glue and dipping glue times can be set on the

machine , normally both ends of silicone gaskets will be dipped with glue for twice .

the adhesive container holds the glue and will release the glue to brush boards by air pressing force .

the silicone adhesive as in paste form will adhere to the brush boards after brusing on .

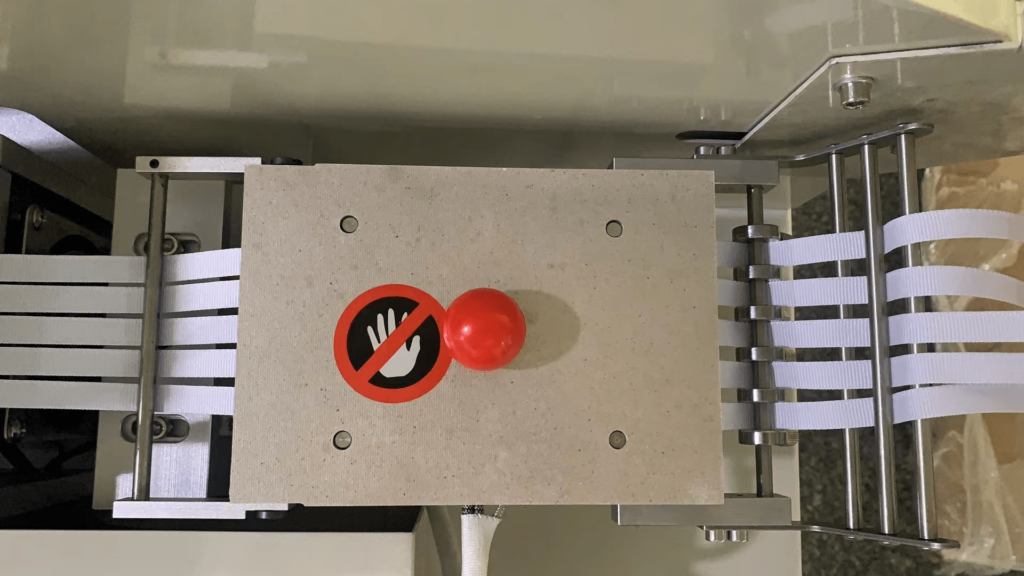

General view

【Warranty】

All the spare parts of the utrasonic shoe loop cutting folding joining machine ES-094 will have one year of free maintainance by changing the spare parts

for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

1SET/ Wooden case (Inside the wooden case will be packed with foam pading material to protect the machine)